- Homepage

- /

- A Comprehensive Guide to Electronic Valve Types: From Basic to Smart Proportional Control

A Comprehensive Guide to Electronic Valve Types: From Basic to Smart Proportional Control

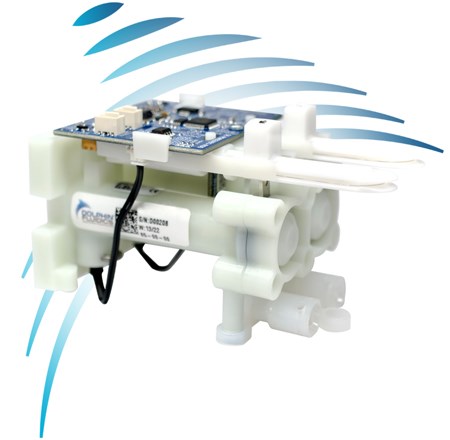

In the world of advanced engineering, from medical devices to industrial automation, precise fluid control is not just a requirement—it's the bedrock of performance, efficiency, and reliability. Traditional mechanical valves have given way to more sophisticated solutions, but even among these, a new standard is emerging. Dolphin Fluidics is at the forefront of this evolution with a new generation of digitally native mechatronic proportional valves, designed to meet the demands of Industry 4.0.

Our smart proportional valves offer unparalleled precision in managing flows and pressures, integrating seamless digital connectivity for real-time data management. They represent a paradigm shift from simple actuation to intelligent fluidic control.

What is the meaning of electronic valve?

An electronic valve, at its core, is a device that uses an electrical or electronic signal to control the flow of a fluid (liquid or gas) through a pipe or a system. Unlike manual valves that require physical interaction, electronic valves can be operated remotely, automatically, and with a high degree of precision.

Learn more about our smart proportional valve

How do electronic valves work?

The working principle of an electronic valve depends on its specific type, but the general process involves three main components:

- The valve body: this is the mechanical part of the valve that contains the orifice and the closure member (like a plunger, diaphragm, or ball) which physically obstructs or allows fluid flow.

- The actuator: this is the component that converts electrical energy into mechanical motion to open or close the valve.

- The control signal: an external electronic circuit provides a signal (e.g., a specific voltage or current) that tells the actuator what to do—whether to open fully, close fully, or modulate to a specific position.

This fundamental mechanism allows for integration into complex automated systems, providing responsive and reliable fluid management that is impossible to achieve with manual intervention.

An overview of common electronic valve types

The term "electronic valve" covers a broad range of technologies, each suited to different applications based on requirements for speed, precision, power consumption, and cost. Understanding these categories is the first step in selecting the right component for your engineering project.

1. Solenoid valves

Solenoid valves are the most common type of electronic valve. They are electromechanical devices that use an electric current to generate a magnetic field, which in turn moves a plunger or armature to open or close an orifice.

- Operation: they are typically binary, meaning they operate in two states: fully open or fully closed (on/off). When the coil is energized, the plunger moves to open the valve; when de-energized, a spring usually returns it to the closed position (in a “normally closed” configuration).

- Applications: ideal for simple on/off tasks such as controlling water flow in irrigation systems or pneumatic automation systems.

- Limitations: they lack the ability to regulate flow precisely. The abrupt on/off action can cause “water hammer” in hydraulic systems, and they can consume significant power when held open for long periods.

2. Motorized valves (electric actuator valves)

Motorized valves use an electric motor to provide the rotational force needed to open and close the valve, often a ball or butterfly valve. The motor is connected to a gearbox to generate enough torque to actuate the valve stem.

- Operation: they are generally slower to actuate than solenoid valves but can handle much higher pressures and flow rates. They can be designed for simple on/off control or for modulating/throttling flow by stopping the valve at intermediate positions.

- Applications: widely used in industrial processes, HVAC systems, and water treatment plants where high torque is needed and actuation speed is not critical.

- Limitations: Their mechanical complexity, larger size, and slower response time make them unsuitable for applications requiring rapid, precise adjustments.

3. Piezoelectric valves

Piezoelectric valves utilize the “piezoelectric effect” where certain ceramic materials change shape when a voltage is applied. This microscopic movement is amplified to actuate a diaphragm or plunger, allowing for extremely fine control over fluid flow.

- Operation: they offer incredibly fast response times (microseconds) and proportional control with very low power consumption, as they only consume power when changing state.

- Applications: perfect for high-precision applications like medical ventilators, gas chromatography, and microfluidics where minimal energy use and high accuracy are critical.

- Limitations: they typically have a limited stroke and force, making them suitable for smaller orifices and lower flow rates.

The evolution: electronic proportional flow control valve technology by Dolphin Fluidics

While the valve types above serve many purposes, the growing demand for dynamic and intelligent systems has driven the development of electronically controlled proportional valves. These devices represent a significant leap forward, bridging the gap between simple on/off control and fully modulated, precise fluid management.

A proportional valve is designed to vary the flow rate of a fluid by changing the position of its closure element in direct proportion to the input signal it receives. Instead of being just “open” or “closed”, it can be 10% open, 50% open, or any position in between, providing a continuous and variable output.

How electronically controlled proportional valves work

These valves use sophisticated actuators that can position the valve spool or plunger with extreme accuracy based on an analog input signal (e.g., 0-10V or 4-20mA). An internal or external control circuit continuously adjusts the power to the actuator to maintain the desired position against varying pressures and flow forces. This closed-loop control allows for a highly stable and repeatable flow rate.

Key advantages of proportional control

- Precision: ability to accurately meter fluids, crucial for chemical dosing, pressure regulation, and mixing applications.

- Efficiency: reduces energy consumption and fluid waste by delivering only the required amount of flow, eliminating the inefficiencies of on/off cycling.

- System simplification: a single proportional valve can often replace multiple on/off valves and complex supporting circuitry, reducing system footprint and cost.

Key applications of electronically controlled hydraulic and pneumatic proportional valves

The versatility of electronic proportional valves makes them indispensable in numerous high-tech industries.

Medical and analytical devices

In medical equipment like dialysis machines, ventilators, and anesthesia delivery systems, patient safety depends on the precise control of gases and liquids. Proportional valves deliver the exact flow rates and pressures required, with the reliability that critical applications demand.

Industrial automation and robotics

In automated manufacturing, electronically controlled hydraulic proportional valves are used to manage the force, speed, and position of hydraulic cylinders with great accuracy. This is essential for robotics, press machines, and material handling systems where smooth and repeatable motion is key.

Coffee machines

One of the most relatable yet demanding applications for proportional valves is in high-end and commercial coffee machines. Achieving the perfect espresso shot requires precise control over water pressure, flow rate, and temperature—all variables that a proportional valve can manage.

- Pressure profiling: an electronic proportional valve allows the barista or the machine's program to dynamically change the water pressure throughout the extraction process. This 'pressure profiling' can highlight different flavor notes in the coffee beans, something a simple solenoid valve cannot do.

- Flow control: the valve can precisely regulate the volume of water, ensuring shot consistency and enabling pre-infusion cycles where a small amount of low-pressure water is introduced to the coffee grounds before the main extraction.

- Stability and repeatability: for a coffee shop serving hundreds of drinks a day, every shot must be consistent. The electronic control ensures that the 100th espresso is identical to the first, regardless of fluctuations in the main water supply.

The search for the perfect electronic valve coffee machine working principle ends with proportional control, which provides the level of nuance required for a truly premium beverage.

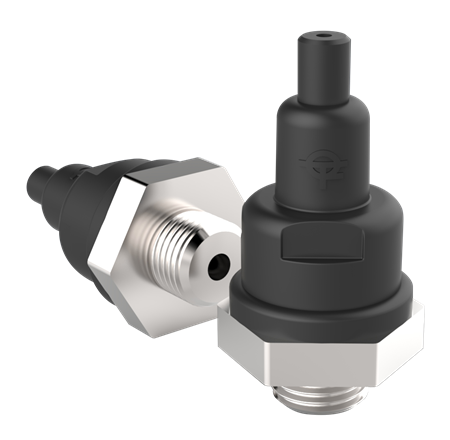

Choosing the right electronic valve: with or without flow control?

An important distinction to make is whether you need a simple proportional valve or one with integrated flow control. A standard proportional valve's output can be affected by changes in inlet pressure. For applications where the flow rate must remain constant regardless of pressure fluctuations, an electronic valve with flow control is necessary. These systems incorporate a flow sensor and a closed-loop controller that automatically adjusts the valve opening to maintain a set flow rate, adding a layer of intelligence and stability to the system.

The Dolphin Fluidics difference: your supplier in digitally native mechatronic valves

At Dolphin Fluidics, we are redefining the market for electronically controlled fluidic valves. Our technology introduces a paradigm shift, moving beyond traditional analog control to a new, digitally native mechatronic standard.

Our smart proportional valves are not just components; they are intelligent nodes in your fluidic system. They are designed to address the core pain points faced by engineers and designers:

- Precision and repeatability: we deliver the ultra-high precision and repeatability needed for the most demanding applications, from medical diagnostics to analytical instrumentation.

- Miniaturization and efficiency: our valves are compact and consume minimal power, enabling the development of smaller, more efficient, and portable devices.

- Digital connectivity: with serial, digital, and wireless connection options, our valves are ready for Industry 4.0 and IoT. They don't just control fluids—they generate valuable data for system monitoring, diagnostics, and optimization.

- Simplified integration: our technology simplifies system design, reducing the complexity and cost associated with integrating traditional fluidic systems.

We empower innovators to build the next generation of advanced systems. If you are struggling with the limitations of conventional valves and need a smarter, more connected, and more precise solution, explore our family of proportional valves.

Contact request

Thank you for your interest Error processing your request. Please retry or contact us.

)