- Homepage

- /

- The proportional valve working principle

The proportional valve working principle

On this page, we will look at:

- The working principle of a proportional valve

- Active water temperature control using DF proportional valve

- Electronic characteristics of proportional valves

- Operational benefits of a proportional valve

- The technology behind Dolphin Fluidics proportional valves

Proportional valves can differ from one another in terms of mechanisms, technology, flow and pressure control, and electronics. However, the precision and efficiency these devices can provide are unequaled.

Dolphin Fluidics proportional valve working principle is that of normally closed valves with proportional regulation. They have an integrated digital system that enables the closed loop control of fluid or pressure rate, avoiding instability and fluctuations that can lead the operation to be off-balance.

As a matter of fact, these devices are modern systems with unique control over fluid and pressure dynamics which doesn’t require a manual intervention on the behalf of the operator and give the opportunity to electronically adjust any drift or troubleshooting in real-time, achieving the best possible performance in many contexts and applications.

The working principle of Dolphin Fluidics proportional valves

The working principle of a proportional valve is a complex system designed to ensure the utmost accuracy in controlling fluid and pressure rate, depending on the specific context or application.

1. Electronic input and signal processing

The operation begins with an electronic command sent from the control system—typically digital, analog, PWM, serial, I²C, or even wireless communication such as BLE. This input defines the target parameter, such as:

-

Desired flow rate

-

Required pressure level

-

Specific temperature or mixing ratio (in multi-fluid systems)

The valve’s integrated electronics interpret this signal and translate it into an actuation command with high precision. Dolphin Fluidics valves feature an embedded digital control board that executes this process instantaneously and with exceptional repeatability.

2. Electromechanical conversion and actuator movement

Once the command is received, the electronic system triggers the actuator. In Dolphin Fluidics designs, the actuator is based on Shape Memory Alloy (SMA) technology, which provides:

-

Smooth and silent motion

-

Ultra-low power consumption

-

Compact form factor

-

High mechanical reliability

The SMA wire undergoes controlled deformation based on the electrical input, producing exact and proportional displacement. This movement drives the internal mechanical components that regulate the valve’s opening window.

3. Flow and pressure regulation through channel design

Inside the valve body, the actuator’s movement modulates the geometry of one or more flow channels. Depending on the architecture:

-

Single-channel valves: regulate one medium (air or liquid).

-

Dual-channel valves: manage mixing, dispensing, or precise ratio control.

The degree of opening is directly proportional to the actuation signal, enabling incremental adjustments rather than abrupt shifts. As a result, the system can achieve:

-

Micro-variation flow control

-

Highly linear response curves

-

Stable pressure regulation even under fluctuating load conditions

4. Closed-loop feedback for real-time precision

What truly distinguishes advanced proportional valves—especially those from Dolphin Fluidics—is the closed-loop feedback system.

Integrated sensors (for flow, pressure, or temperature) constantly monitor the actual operating conditions. This data is fed back into the microcontroller, which compares real values with the desired setpoints.

If discrepancies occur due to drift, environmental conditions, or system disturbances, the valve automatically corrects its position in real time.

Closed-loop control ensures:

-

No drift over time

-

Consistent accuracy across millions of cycles

-

Stability even in dynamic or stressful operating environments

-

Predictable and safe system behavior

5. Embedded intelligence and IoT connectivity

Modern proportional valves have evolved into smart mechatronic units. Dolphin Fluidics integrates advanced digital features directly into the device, such as:

-

Real-time diagnostics

-

Data logging

-

Predictive maintenance signals

-

Communication via RS485, I²C, BLE

-

Remote parameter tuning

-

Integration with cloud platforms and mobile apps

This level of intelligence transforms the valve into an active component of the broader automation ecosystem, capable of adapting autonomously and reporting its operational status.

6. Thermo-fluidic applications and autonomous mixing

In temperature-regulated systems—such as water mixing applications—the valve continuously adjusts flow to maintain the desired output temperature.

For example:

-

An NTC temperature sensor measures the outlet temperature.

-

The valve receives real-time temperature feedback.

-

The actuator automatically modulates cold or hot water flow (depending on configuration) to maintain the target temperature.

This ensures consistent thermal performance even when inlet temperatures or pressures vary.

Do you want to know more about our proportional valves' working principle?

Contact us for further information

Key characteristics of Dolphin Fluidics’ proportional valves

- Air/liquid dosing, dispensing and mixing in a single digital device

- Actuator technology based on Shape Memory Alloy technology, totally noiseless operation

- Closed loop proportional control keeping high accuracy, no drift and stability over time

- Input for external sensors (P,Q,T) to close functional loops in the valve

- Reliable sealing system with medium separation

- Wireless data communication and remote control

- Small, light, very low power operation (10-20 times less than standard actuators)

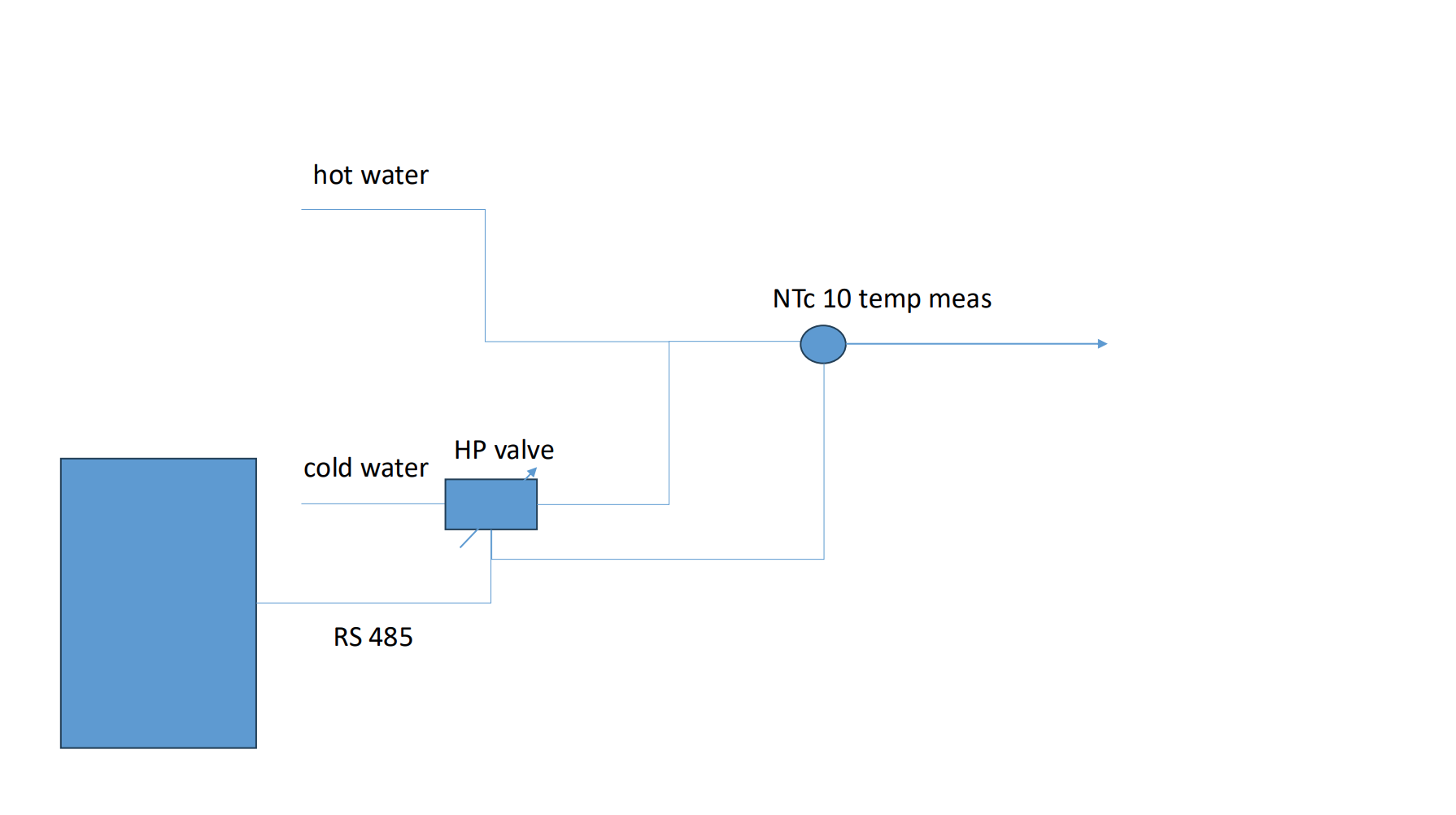

Active water temperature control using DF proportional valve

- Hot and cold water inlets: the two flows are mixed.

- HP valve (High Precision valve): the proportional valve that continuously regulates the cold water flow. It’s not just an on/off device but adjusts its opening based on the electronic control signal.

- RS485: a serial communication interface between the electronic board and the control system. It allows sending commands to the valve and receiving diagnostic data.

- NTC 10 temp meas: a temperature sensor (NTC = Negative Temperature Coefficient, 10 kΩ) that measures the outlet flow temperature. It’s connected directly to the valve PCB and gives the temperature signal to the valve to close the loop.

- Overall operation: the system dynamically regulates the hot/cold water mixture through the proportional valve, reading the actual temperature with the NTC and automatically adjusting the valve opening to keep the desired temperature constant.

Electronic characteristics of proportional valves

- Operating voltage: 5–24 VDC → compatible with multiple systems.

- Actuation power: 0.6 W per channel at 5 V → very low, therefore efficient.

- Standby power: 0.2 W at 5 V → reduced consumption when idle.

- Rise time (150 ms): valve response time to command → very fast.

- Service life: millions of cycles (depending on application).

- Proportional control inputs: analog, digital, PWM, serial, I²C, BLE → high flexibility for different automation systems.

- Sensor inputs: analog / I²C → direct connection for probes (such as the NTC 10).

- Communications: serial, I²C, BLE, digital I/O, status LEDs → versatile and easily monitored interface.

Operational benefits of a proportional valve

The proportional valves working principle offers a multitude of benefits to those systems that require in-depth control over fluids and pressure. Among these advantages, we can find:

- Precision with minimal fluctuation: these electronic devices are exact in maintaining specific flow rates and pressure.

- Lower energy consumption: the lower the drift, the more the operational efficiency. The proportional valves mechanism allows high levels of precision, allowing companies to save energy by eliminating the full-on/full-off cycle of solenoid valves.

- Responsiveness: proportional valves are extremely responsive. This contributes significantly to adjusting parameters in real time, preventing and accommodating sudden changes even under operational stress.

- Electronics: the digitization and automation of new generation proportional valves have modernized these devices where every single part is interconnected in order to allow operators to be always updated about the valves’ activity, minimizing errors, and enhancing consistency.

- Specific proportional valves for gases and proportional flow control valve for water and liquids.

Find out more about the mechanism, the operational benefits and the application of proportional valves

Read here

The technology behind Dolphin Fluidics proportional valves

Dolphin Fluidics has always been committed to innovation and progress concerning the proportional valve working principle. Our models have been designed to enhance both performance and reliability, using top-tier materials and the most advanced technologies.

A crucial aspect of our proportional valves is the integration of smart mechatronic elements, such as shape memory alloy-based actuators and digital electronic which take these valves to new heights in terms of IoT communication for remote management and data transfer. All this in a single device.

Our devices are not just smart because they are responsive and they can connect to cloud systems and mobile platforms. In fact, they are highly efficient, compact, resistant, and customizable based on the target market demands to achieve the best results in many different contexts.

Do you want to know more about our proportional valves' working principle?

Contact usContact request

Thank you for your interest Error processing your request. Please retry or contact us.

)